Innovating the Future with

LiDAR Semiconductors

The Leading Solution for Cost Effective, High Performance LiDAR

Semiconductor For LiDAR Technology Businesses

WaveDyne FMCW LiDAR semiconductor technology aims for the best price, performance, and reliability.

We strive to provide innovative FMCW LiDAR solutions across various industries.

LiDAR Market Barriers:

High Cost

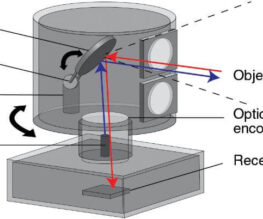

Mechanical scanners, including polygon / galvano scanners, have many mechanical components, causing slow commercialization due to high prices.

A true solid state scanner without mechanical components is necessary.

Complexity

Mechanical based scanners require custom manufacturing due to the absence of off-the-shelf products and have limitations in miniaturization.

Assembly and calibration efforts increase, and automation equipment is needed.

Fiture: Utmel , 2021, How does Lidar Work?

Limitations

Pulse LiDAR's optical power output can cause heating and eye safety issues and is vulnerable to poor weather conditions like snow, rain, and fog.

Mechanical based scanners face reliability and lifespan issues due to vibration and heating, failing to meet the LiDAR specifications required by the automotive industry.

Lack of

[KEY COMPONENTS]

FPGAs or DSPs can significantly constrain costs, sizes, heating, and performance.

LiDAR-specific ASIC is necessary to address these issues.

Key Components:

WaveDyne FMCW LiDAR Semiconductors

New Architecture

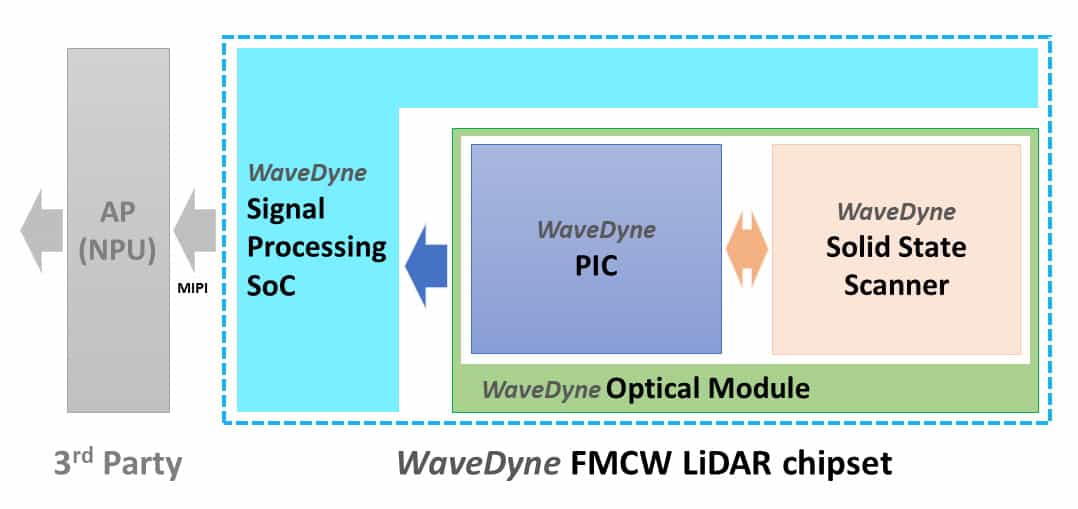

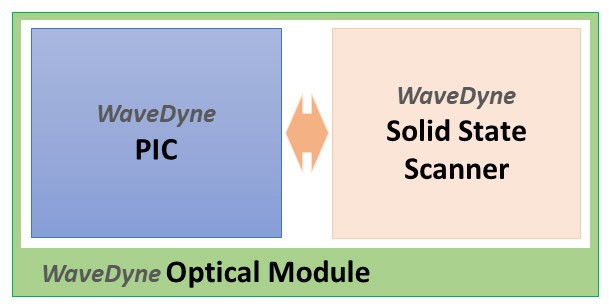

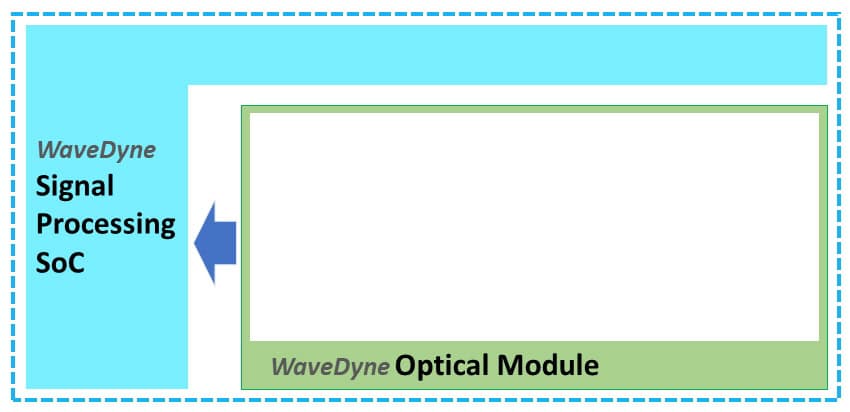

The WaveDyne optical module consists of a true solid state scanner and FMCW photonic integrated circuit (PIC) based on semiconductor technology.

The WaveDyne SoC internally processes the FMCW lidar signal generated by the optical module and then transfers it to an external application processor (AI enabled).

WaveDyne's semiconductor based architecture allows vendors to commercialize FMCW lidar at camera level prices while minimizing development investment.

Core Technology and

Competitiveness

Optical Module

- Configuration: Solid-state scanner, photonic circuits, and essential wiring

- Advantages: No need for complex assembly or calibration. Automation equipment is not required. Solves issues with vibration and overheating.

Dedicated SoC

- Delivers excellent value for the cost

Reduces the need for extensive development resources

- Lowers costs for client's investment

FMCW LiDAR Technology

- Achieves the longest detection distance with the least amount of light

- Overcomes problems with overheating and ensures eye safety

- Performs well in tough conditions using a 1550nm wavelength

Technology for Full Autonomous Driving

Core Technology

- Technology for controlling low-power lasers over long distances and reducing noise

Competitiveness

- Integrated development and supply of solid-state scanners, PIC, and signal processing SoCs

Performance

- Resolution, performance, and size on par with ADAS cameras

- Resolving issues with overheating

WaveDyne fulfills automakers' LiDAR requirements by solving performance, cost, size, and overheating issues.

FMCW LiDAR

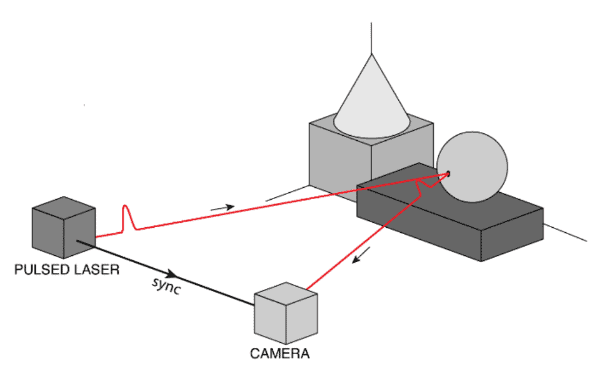

Pulse LiDAR calculates distance by measuring the round-trip time of an optical pulse to the target.

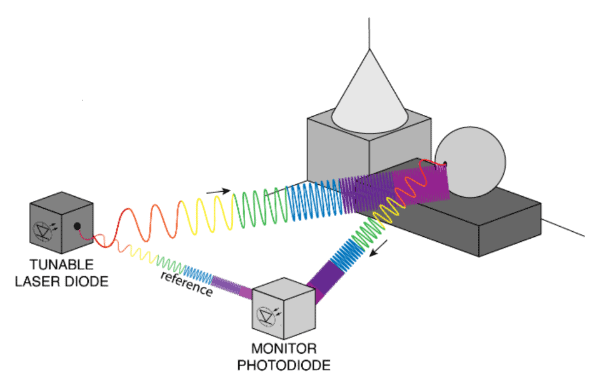

In contrast, FMCW LiDAR measures distance and speed simultaneously using the interference between frequency-modulated output light waves and their reflected light waves from the target.

Pulse 3D LiDAR

FMCW 4D LiDAR

Figures: Federica Villa, 2021, "SPADs and SiPMs Arrays for Long-Range High-Speed Light Detection and Ranging (LiDAR)", Sensors

Pulse 3D LiDAR

Only 3D spatial information

Signal noise and low reception efficiency in snow, rain, fog, and dust conditions

Interference from external light sources

Safety concerns with high power lasers

Challenges in reducing prices due to high cost components

Pulse signal processing limitations

VS

FMCW 4D LiDAR

6D information (3D, speed, reflectivity, and material)

Stable signal reception in all conditions

No interference from external light sources

Eye safety with low power lasers

Low price at $300

Advanced signal processing through continuous signals

Core Technology and Competitiveness

Autonomous driving software simplification and safety enhancement

Minimal impact from snow, rain, fog, and dust

Minimal influence from sunlight and headlights

Eye safety with low power lasers

Core component development possible through semiconductor processes

Expanded solid state scanner options, system miniaturization

Our Vision

WaveDyne pioneers the democratization of LiDAR technology across autonomous mobility, infrastructure, and automation with our innovative FMCW optical modules and signal processing SoC.

In collaboration with industry partners, we deliver market differentiating solutions that integrate high performance with cost efficiency in a flexible structure.

We proactively expand strategic partnerships, strengthen customer communication, and pursue continuous innovation.

Driven by innovation and partnership, we commit to advancing the LiDAR industry.

Semiconductor For LiDAR Technology Businesses

We are looking for opportunities to grow and collaborate together.

We welcome your inquiries.

contact@wavedyne.ai

Phone

+82-10-8890-5550

Address

B - 910, Daesung D-POLIS, 606, Sebusaet-gil, Guemcheon-gu, Seoul , Korea

© 2024 All rights reserved. WaveDyne Inc. | GLOBAL LEADING FMCW LIDAR SEMICONDUCTOR SUPPLIER BY 2030